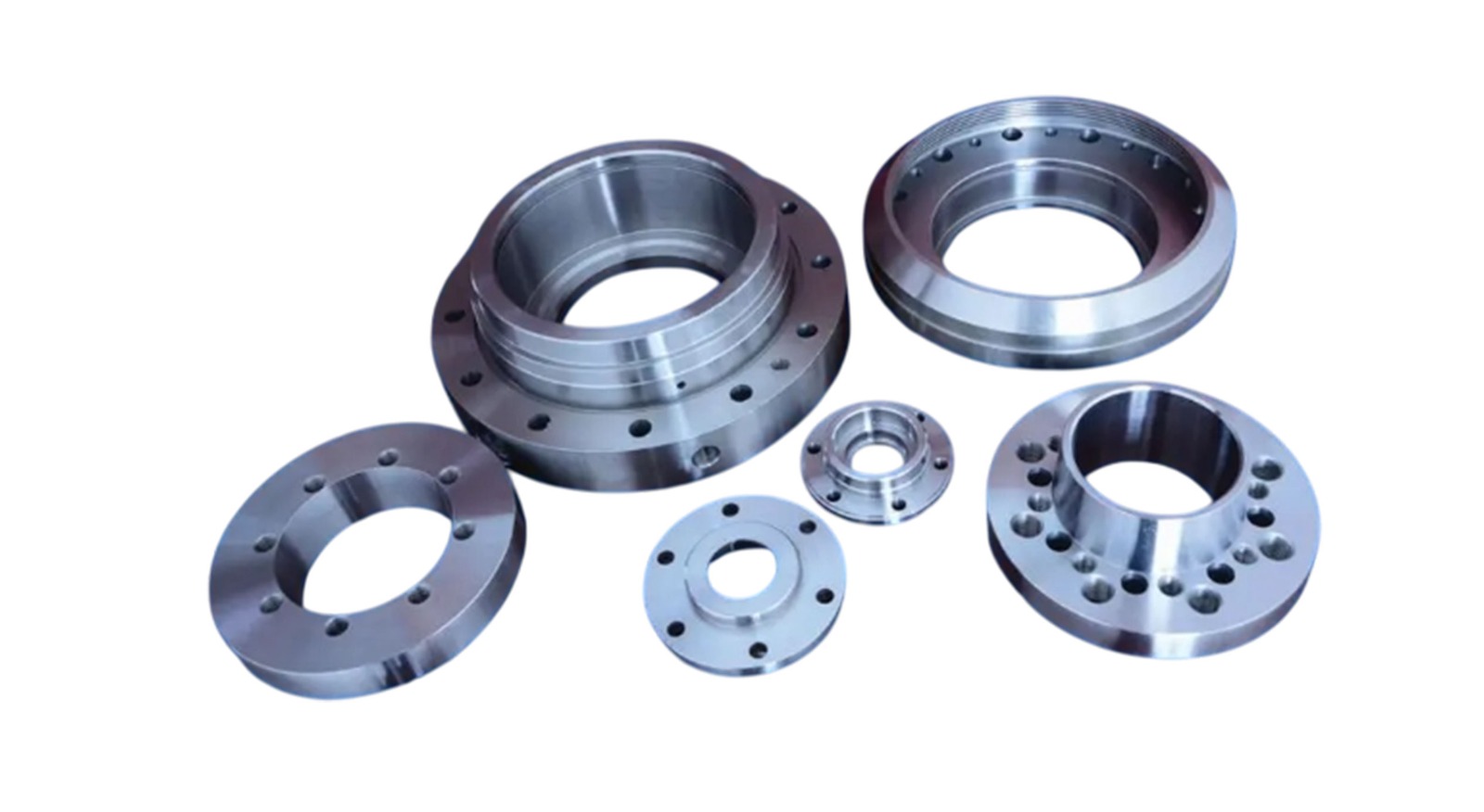

Precision Machined Component Manufacturers in USA

Sahyadri Industries is one of the leading Precision Machined Component Manufacturers, and Suppliers in USA. We are delivering high-quality, custom-designed components tailored to meet the diverse industrial needs. As a trusted one-stop solution provider, we specialize in producing precision machined components that meet the customers demand.

Precision Machined Component Manufacturers in USA

We use every type of machined component parts such as Brass Machined Parts or CNC Bending Solutions. It has uncompromising quality and unmatched reliability. We make sure that all the products we produce are of the best industry level and meets the every unique demands and expectations of customers.

Types of Machined Components

A leading machined component manufacturers in USA, we are providing the best and high quality of machined components such as:

- Custom Machine Parts: Made to your specifications with full material and finish capabilities. We involve our customers closely from design to manufacture, to make each component to their specific specifications. Since we can customise parts, we can make the most unique specs in different industries. One prototype to the production run, we offer bespoke solutions to any project.

- SPM Machined Parts: Designed for Specialist Purpose Machines, that is to ensure maximum efficiency in high-volume production environments. Our specialty is making parts which make the fullest possible use of specialist equipment. Such parts can have a dramatic effect on bespoke equipment’s productivity and efficiency. We collaborate with customers to create and manufacture parts which enable them to meet their own exact manufacturing needs.

- VMC Machined Parts: Made on VMCs to achieve high-speed, multi-axis precise components. VMCs allow us to create parts with better accuracy, therefore the best choice for complex and detailed parts. We can achieve parts of high precision and minimal variation using these machines. We use advanced VMC technology to make sure our parts achieve the best tolerances.

- Lath Machined Parts: Produced on advanced lathes to undertake complex turning and polishing operations. The parts require high finishing to offer the required product, and we ensure accuracy in delivering it in each process. Our advanced lathes provide us with strict tolerances which play a crucial role in giving overall quality to the parts. We can achieve complex geometry and fine design with high precision.

- Mild Steel CNC Machined Components: Accurately machined on our CNC equipment for where there is a need for high tolerance accuracy. We combine the best of technology of CNC with skilled craftsmanship to provide components of utmost quality. Our CNC equipment operates at a fast and effective pace in the manufacturing of small and large quantity. We produce extremely fit components, smooth as silk and ensuring long lasting reliability.

- Mild Steel Machined Parts: Their strength and machinability have made them globally renowned and utilized in all heavy equipment. We supply high mechanical strength and toughness requirement parts. Mild steel is so versatile that it’s used in all manufacturing and construction sectors. Our mild steel parts are specifically designed for high performance along with cost.

- Aluminium Machined Parts: Durable yet light and applied extensively in the aerospace and automotive industries. We apply cutting-edge machining to manufacture cost-effective and reliable parts. Aluminium parts possess an outstanding strength-to-weight ratio, thus applied where weight saving is critically essential. Our aluminium machined parts are of industry-leading strength, precision, and reliability standards.

- Brass Machined Parts: The most appropriate for plumbing and electrical applications since they conduct and resist corrosion more effectively. We use higher-quality brass alloys to ensure maximum performance and longevity. Our brass parts are accurately machined according to the unique needs of each project. They are primarily applied in electrical connectors and fittings where they require high conductivity.

Features of Machined Components

One of the best steel machined components manufacturers in USA, our all-types of services are included with new features inside such as:

- Advanced Tolerances: We provide a maximum of ±5 microns on our state-of-the-art CNC and VMC machines. This attention to detail provides us with confidence that every component exactly fits together and functions flawlessly. We keep our machinery current with continuous upgrades to accommodate evolving customer expectations for narrower tolerance. Our commitment to maintaining these tight tolerances distinguishes us in the market.

- Material Flexibility: From brass and aluminium to mild steel, and with heat treatment and surface finishing versatility an option. We possess a variety of materials on hand to serve the specific needs of different industries. Our ability to machine diverse materials makes us industry leaders at offering turnkey solutions to any project. Either a standard or special material, we have equipment and expertise to address it.

- Corrosion & Wear Resistance: Improved by plating, anodizing, or powder coating as needed for application. The coatings increase parts' life and performance, especially in harsh applications. Our emphasis on finishing is that all parts are corrosion- and wear-resistant. We supply them to make your parts more durable and even more attractive.

- Customization Ready: Since we have CAD/CAM designing team and CNC programming laboratory, we are capable of including any spec with ease. We provide specially designed solutions as per client specification whether it is a special design or a special choice of material. We pride ourselves on converting your concept into high-performance machined product. We manufacture every product keeping your particular need as the point of origin.

- Smart Machining: Incorporation of IoT-based machining centers for in-process control and monitoring in real-time. It helps us attain maximum efficiency, error-free processes, and constant quality in production. With the latest smart machining technologies, we are industry pioneers and offer better services. It also helps us avoid downtime and results in faster delivery.

Advantages of Machined Component

All these innovative ways of our machined parts are extremely advantageous such as:

- Even Production: Advanced technology equipment ensures even precision of parts by batch quantity.

- Cost-Saving Solutions: Cost-effective production processes reduce material wastage to a great extent, providing cost-saving solutions to clients.

- Ambitious Services: Provides various services, including CNC bending, surface treatments, and sub-assembly support, in a way that all the customers have a one-stop solution.

Applications of Machined Components

Being the best machined Components manufacturing service and machined parts suppliers in USA, our all machined parts are full of new feature and widely utilized in various applications like:

- Automotive Industry

We produce performance CNC machined engine, suspension, and gearbox components. Each component is produced to automotive specifications, rigorously tested under simulated normal operating conditions. Prototype to volume manufacturing, we fulfill your precision and performance requirements in the entire car industry. - Electrical & Electronics

Our machined brass parts find extensive use in terminals, connectors, and interfaces of circuits. Due to their superior electrical conductivity as well as resistance to corrosion, brass is particularly capable of supporting mission-critical electronics. We utilize strict tolerances and technical specs in ensuring that our components work impeccably in high-demand electrical systems. - Aerospace & Defense

We provide accurate aluminum components appropriate for aerospace and defense applications. They are not heavy yet extremely robust—designed to operate at extreme altitude, pressure, and temperature conditions. There are strict quality checks to ensure that each component meets international aerospace standards for durability and safety. - Industrial Automation

Our SPM machined components are designed from scratch for highly efficient custom manufacturing equipment. They are designed specifically to integrate with custom machinery and simplify repetitive motion in these mass production factories. We provide dimensional precision and functional reliability—allowing for consistent production and minimizing downtime. Within manufacturing environments. - Construction Machinery

We provide long-lasting mild steel CNC-turned components that can tolerate harsh operating conditions. In construction equipment, loader, and crane, our products provide enhanced toughness as well as fatigue strength. Our components are tested to provide more than their specifications performance to provide increased service life under constant mechanical stress. - Medical Devices

We manufacture sanitary, precision-machined medical and healthcare industry parts. Cleanroom-compatible parts for medical devices, diagnostic products, and lab equipment are manufactured to worldwide cleanliness and precision standards or higher. Functional reliability and patient safety are of utmost importance. - Agricultural Equipment

Our turned machined parts for tillers, tractors, harvesters, and farm machinery are made to withstand loads and last longer. They improve functional life and performance. To withstand challenging terrain and cyclic loading, they optimize agricultural harvests.

Sahyadri Industries is a dominant Precision machined component manufacturers, suppliers in USA, we are dedicated to creating robust, effective, and innovative solutions to industrial problems. With a focus on quality and customisation, we are a design-to-delivery end-to-end solution partner. Our ability, infrastructure, and service levels lead us to be a highly regarded name in machining. We are experts in customised machine components that precisely fulfil client requirements for function and fit. Our in-house CNC bending operations allow us to provide customised profile and frame shapes for specific applications. We are dedicated to ongoing investment in technology as well as skilled manpower to remain abreast of world manufacturing advancements. For more information, contact us today!

Frequently Asked Questions (FAQs)

Rotated parts are to be kept in specified, rust-inhibiting coated bins or containers in a manner so that they will not oxidize and become mixed up. Store them in stackable containers with padding so the surfaces do not get scratched during storage.

Store components in a temperature-controlled, dry area with VCI paper or desiccants. Rotate and inspect periodically to prevent corrosion or degradation over time.

Yes, cylindrical parts are suitable for vertical racks with foam or rubber inserts. Just make sure to securely insert them in position so they will not fall or become scratched.

Yes. Combining different materials will produce galvanic corrosion or contamination, particularly between ferrous and non-ferrous metals.