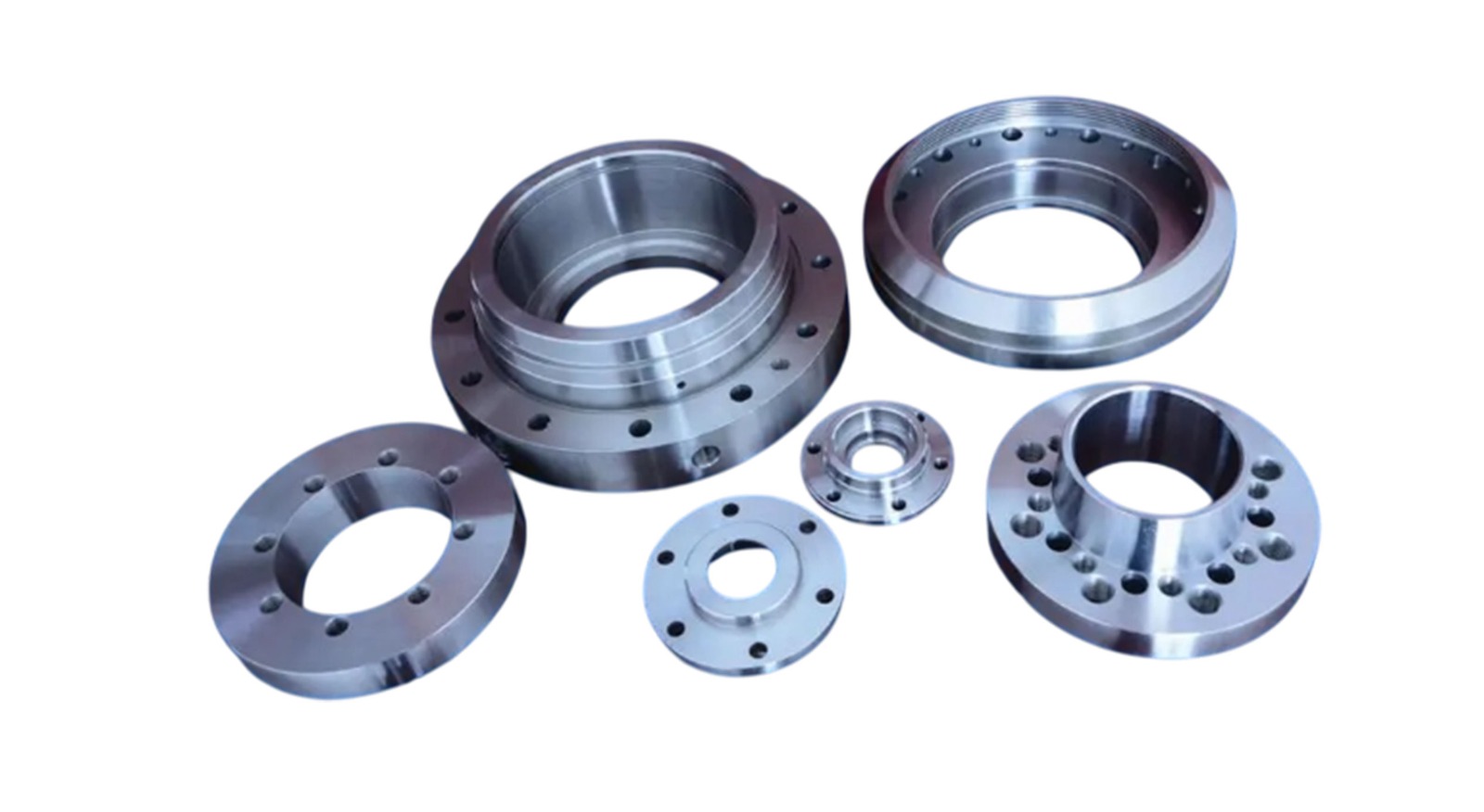

Machined Component Manufacturers in India

Sahyadri Industries is recognized as a well-known machined component manufacturers and suppliers in India. We specialize in delivering customized, high-performance components across a comprehensive range at affordable Prices. We Provide customized machining solutions with state-of-the-art technology and industry-accepted material. We make sure that all the products we produce are of the best industry level and surpass expectations of customers. We are quality-conscious in everything we do. We have maintained our customers satisfied through long-term relationships by providing quality products and services at all occasions.

About Machined Component

We stand as leading Machined component Manufacturers and Suppliers in India, we serve a diverse range of industries including automotive, aerospace, electronics and renewable energy. We are specialized in tailor-made machine solutions to specific customer needs.as well we support our customers at every stage ensuring the smooth communications and transperent execution.

Types of Machined Components

A leading machined component manufacturers in India, we are providing the best and high quality of machined components such as:

- Brass Machined Parts: The most appropriate for plumbing and electrical applications since they conduct and resist corrosion more effectively. We use higher-quality brass alloys to ensure maximum performance and longevity. Our brass parts are accurately machined according to the unique needs of each project. They are primarily applied in electrical connectors and fittings where they require high conductivity.

- Aluminium Machined Parts: Durable yet light and applied extensively in the aerospace and automotive industries. We apply cutting-edge machining to manufacture cost-effective and reliable parts. Aluminium parts possess an outstanding strength-to-weight ratio, thus applied where weight saving is critically essential. Our aluminium machined parts are of industry-leading strength, precision, and reliability standards.

- Mild Steel Machined Parts: Their strength and machinability have made them globally renowned and utilized in all heavy equipment. We supply high mechanical strength and toughness requirement parts. Mild steel is so versatile that it's used in all manufacturing and construction sectors. Our mild steel parts are specifically designed for high performance along with cost.

- Mild Steel CNC Machined Components: Accurately machined on our CNC equipment for where there is a need for high tolerance accuracy. We combine the best of technology of CNC with skilled craftsmanship to provide components of utmost quality. Our CNC equipment operates at a fast and effective pace in the manufacturing of small and large quantity. We produce extremely fit components, smooth as silk and ensuring long lasting reliability.

- SPM Machined Parts: Designed for Specialist Purpose Machines, that is to ensure maximum efficiency in high-volume production environments. Our specialty is making parts which make the fullest possible use of specialist equipment. Such parts can have a dramatic effect on bespoke equipment's productivity and efficiency. We collaborate with customers to create and manufacture parts which enable them to meet their own exact manufacturing needs.

- Lath Machined Parts: Produced on advanced lathes to undertake complex turning and polishing operations. The parts require high finishing to offer the required product, and we ensure accuracy in delivering it in each process. Our advanced lathes provide us with strict tolerances which play a crucial role in giving overall quality to the parts. We can achieve complex geometry and fine design with high precision.

- VMC Machined Parts: Made on VMCs (Vertical Machining Centers) to achieve high-speed, multi-axis precise components. VMCs allow us to create parts with better accuracy, therefore the best choice for complex and detailed parts. We can achieve parts of high precision and minimal variation using these machines. We use advanced VMC technology to make sure our parts achieve the best tolerances.

- Custom Machine Parts: Made to your specifications with full material and finish capabilities. We involve our customers closely from design to manufacture, to make each component to their specific specifications. Since we can customise parts, we can make the most unique specs in different industries. One prototype to the production run, we offer bespoke solutions to any project.

Features of Machined Components

One of the leading Steel machined component Suppliers in India, our all-types of services are included with new features inside such as:

- Brass Machined Parts: The most appropriate for plumbing and electrical applications since they conduct and resist corrosion more effectively. We use higher-quality brass alloys to ensure maximum performance and longevity. Our brass parts are accurately machined according to the unique needs of each project. They are primarily applied in electrical connectors and fittings where they require high conductivity.

- Aluminium Machined Parts: Durable yet light and applied extensively in the aerospace and automotive industries. We apply cutting-edge machining to manufacture cost-effective and reliable parts. Aluminium parts possess an outstanding strength-to-weight ratio, thus applied where weight saving is critically essential. Our aluminium machined parts are of industry-leading strength, precision, and reliability standards.

- Mild Steel Machined Parts: Their strength and machinability have made them globally renowned and utilized in all heavy equipment. We supply high mechanical strength and toughness requirement parts. Mild steel is so versatile that it's used in all manufacturing and construction sectors. Our mild steel parts are specifically designed for high performance along with cost.

- Mild Steel CNC Machined Components: Accurately machined on our CNC equipment for where there is a need for high tolerance accuracy. We combine the best of technology of CNC with skilled craftsmanship to provide components of utmost quality. Our CNC equipment operates at a fast and effective pace in the manufacturing of small and large quantity. We produce extremely fit components, smooth as silk and ensuring long lasting reliability.

- SPM Machined Parts: Designed for Specialist Purpose Machines, that is to ensure maximum efficiency in high-volume production environments. Our specialty is making parts which make the fullest possible use of specialist equipment. Such parts can have a dramatic effect on bespoke equipment's productivity and efficiency. We collaborate with customers to create and manufacture parts which enable them to meet their own exact manufacturing needs.

- Lathe Machined Parts: Produced on advanced lathes to undertake complex turning and polishing operations. The parts require high finishing to offer the required product, and we ensure accuracy in delivering it in each process. Our advanced lathes provide us with strict tolerances which play a crucial role in giving overall quality to the parts. We can achieve complex geometry and fine design with high precision.

- VMC Machined Parts: Made on VMCs to achieve high-speed, multi-axis precise components. VMCs allow us to create parts with better accuracy, therefore the best choice for complex and detailed parts. We can achieve parts of high precision and minimal variation using these machines. We use advanced VMC technology to make sure our parts achieve the best tolerances.

- Custom Machine Parts: Made to your specifications with full material and finish capabilities. We involve our customers closely from design to manufacture, to make each component to their specific specifications. Since we can customise parts, we can make the most unique specs in different industries. One prototype to the production run, we offer bespoke solutions to any project.

Benefits of Machined Component

These all new types of our machined components are highly beneficial such as:

- Production Consistency: Advanced machinery ensures consistent component accuracy regardless of batch size.

- Cost-Effective Solutions: Lean manufacturing practices minimise material waste, resulting in cost-effective solutions for customers.

- omprehensive Services: Offers a range of services, including CNC bending, surface finishing, and sub-assembly support, providing a one-stop solution for customers.

Our Manufacturing Service Procedure

- Manufacturing Process: Streamlined for speed, traceability, and quality.

- Design Phase: Client requirements are converted into accurate 2D/3D CAD drawings with emphasis on function and performance.

- Material Selection: Material selection based on strength, machinability, application, and other parameters such as weight, durability, and corrosion resistance.

- Surface Treatment Options: Anodizing, nickel plating, powder coating, etc.

- Quality Control Measures: Stringent inspection through digital measuring instruments and rigorous testing.

- Packaging and Shipping: Proper packaging, timely dispatch, and proper documentation.

Applications of Machined Component

Being the best machined parts suppliers and manufacturing service providers in India, our all types of machined parts are included with new feature and highly used in multiple applications such as:

- Automotive Industry: Performance CNC machined parts for engine, suspension, and gearbox. We produce parts which can bear the severity of automotive use. We have every part thoroughly tested to make sure it will be able to bear the severity of actual application. From a prototype to production, we can do your requirement.

- Electrical & Electronics: Machined Brass Parts are utilized in connectors and terminals. We manufacture parts that meet the stringent specifications of the electrical world. Brass is utilized extensively due to its high conductivity and corrosion resistance. Our machining gives the parts to function correctly in mission-critical applications.

- Aerospace & Defense: Machined Aluminium Components of long life for high altitude. Our components are made with utmost quality and reliability required in aerospace use. We implement the most advanced technology available to ensure that every component is not only long lasting but also light weight. The components are pushed to the extreme to determine if they would be able to handle extreme conditions or not.

- Industrial Automation: SPM machined parts for custom manufacturing machinery. We create and design the parts to enable the use of custom equipment to be more efficient. The parts enhance the automation process in mass production. We ensure our parts are a perfect fit in your manufacturing plants.

- Construction Machinery: Durable Mild Steel CNC Machined Parts - made to perform in the most challenging conditions. We make parts that are meant to provide significant grilling space in the construction sector. We have parts of mild steel that are known as tough and long-lasting despite harsh conditions. Our parts are subjected to an exhaustive test of their performance against harsh conditions.

- Medical Devices: Precise machining for sanitary and clean components. We appreciate the requirement of precision for medical use. Our components are manufactured to surpass top quality and sanitary standards. From surgical equipment to diagnostic equipment, we provide high-quality and precise components for medical use.

- Agricultural Equipment: CNC bendable heavy load custom parts. We create parts which are strong enough to endure an agricultural equipment condition. Our parts are produced to be used with heavy duty and are very critical to enhance agricultural efficiency. Our parts are engineered in a way that they are strong as well as durable, in exchange they enable your equipment to perform at its maximum level.

Sahyadri Industries well known Machined Component Manufacturers in India and Suppliers in India. We are dedicated to creating robust, effective, and innovative solutions to industrial problems, With a focus on quality and customisation, we are a design-to-delivery end-to-end solution partner. Our ability, infrastructure, and service levels lead us to be a highly regarded name in machining.

Frequently Asked Questions (FAQs)

Turned components should be stored in labeled, anti-rust coated trays or bins to prevent oxidation and mix-ups. Choose stackable units with padding to avoid surface damage during storage.

Ensure components are stored in a dry, temperature-controlled space with desiccants or VCI paper. Regular inspection and rotation help avoid corrosion or degradation over time.

Yes, vertical racks with foam or rubber inserts are effective for cylindrical components. Just ensure they are securely positioned to avoid falling or getting scratched.

Absolutely. Mixing materials can cause galvanic corrosion or contamination, especially between ferrous and non-ferrous metals.