Infrastructure

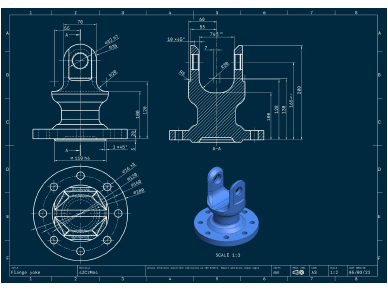

Design & Engineering

Our teams of experienced engineers are committed to your goals and strive to produce the results that you expect from us.

In-house Capabilities

Design & Manufacturing of Welding Fixtures, Inspection Fixtures, Stamping Tools (Press Tools) Design suggestions to customer during initial review for better productivity & quality. 3D Design solutions to Customer in situations like zero hour development. Proto or soft tool development e.g. Temporary Welding Fixtures, Soft stamping tools Proto sample manufacturing using 3D software Well trained staff for 3D designing using CATIA/Auto CAD software

Metallurgical Lab

We worked closely with customers to understand their requirements & developed capability for in-house testing. We can verify that welds have the strength, hardness, ductility, or other material properties required for their intended application per your specification or standard quality procedures before that part, component, equipment, or production lot, is put into service.

Inspection Capabilities

Portable Arm CMM (FARO) Single Axis Measuring Instrument (MITUTOYO) Digital Protractor for Angle Measurement (MITUTOYO) Surface Roughness Tester Paint Inspection Instruments (DFT, Adhesion and Gloss test) Rockwell Hardness Tester for Surface Hardness Test Vickers Micro Hardness Tester for Effective case depth measure Dino Capture Setup for Weld penetration Test Stereo zoom Microscope for Macro Inspection Metallurgical Microscope for Micro Inspection Erichsen Cupping Test. Etc.

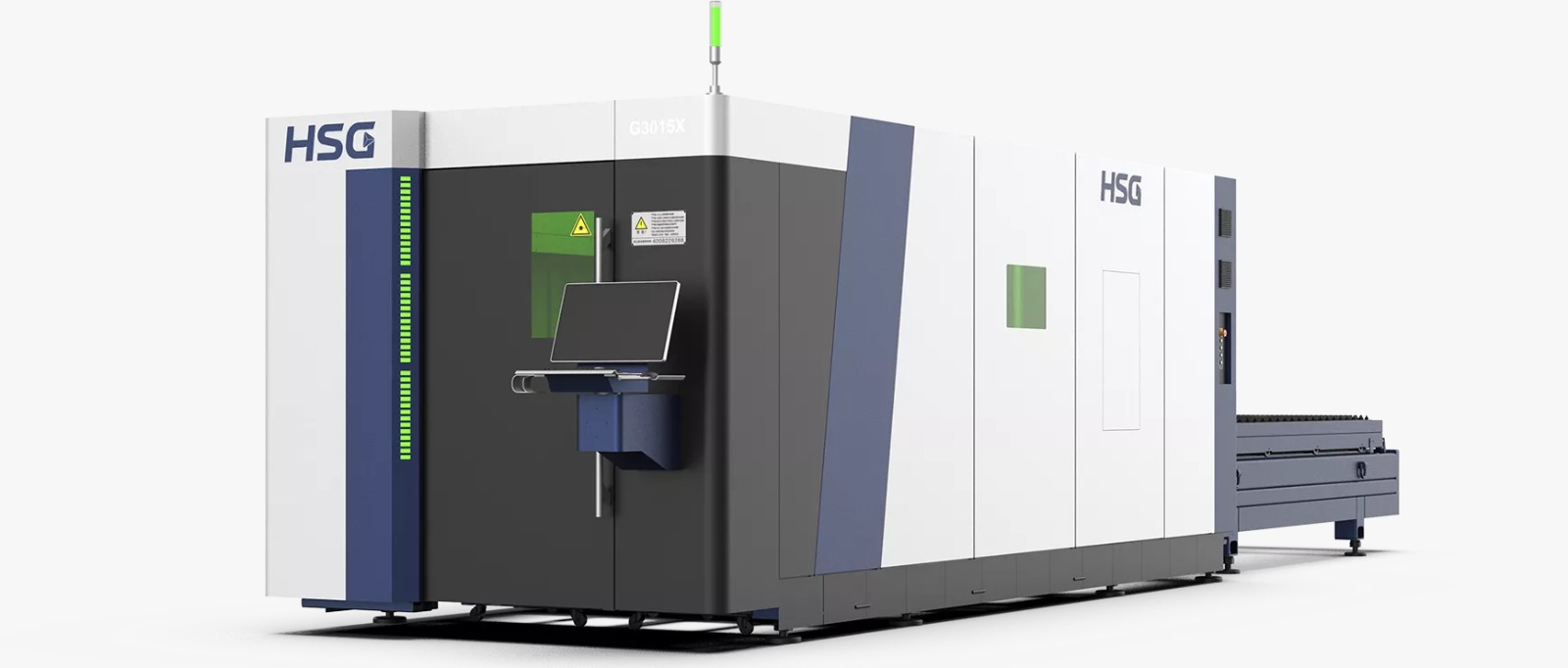

Fiber Optic Laser Capabilities

Fiber optic laser cutters utilise amplified light that is channeled through a fiber optic cable. The light is then straightened and delivered by a lens that is hyper focused on the material being cut. This delivery system provides extremely accurate cutting of numerous types of materials in various thicknesses. Laser cutters can be customised to cut nearly any material of any thickness to exact specifications. It’s fast, accurate, and can be quickly and easily adjusted to meet the changing needs of the market or a specific product. It’s also a cleaner process than most cutting options

CNC Bending Machine

A CNC Bending Machine is an advanced metal forming machine that uses computer numerical control (CNC) to automate and precisely bend metal sheets, tubes, and profiles. It is widely used in industries requiring high-precision bending, such as automotive, aerospace, construction, and industrial fabrication.

Press Shop

A Press Shop is a facility where metal sheets are processed into finished components using mechanical, hydraulic, or pneumatic presses. It plays a key role in industries like automobile, aerospace, electrical appliances, and general engineering.

VMC Machine

A VMC (Vertical Machining Center) Machine is a type of CNC milling machine where the spindle is oriented vertically. It is widely used in industries like automotive, aerospace, tool & die making, and general metal fabrication for precise milling, drilling, boring, and cutting operations.

CNC Machine

A CNC (Computer Numerical Control) Machine is an automated machine tool that uses pre-programmed computer software to control machining operations such as cutting, drilling, milling, and shaping. CNC machines are widely used in industries like automotive, aerospace, electronics, and metal fabrication for high-precision manufacturing.

CNC Tube Bending

We make a point to use only the best CNC tube benders that meet our stringent standards. Thanks to the productivity and reliability of these machines, we’re able to save time and money and pass the savings along to our customers. CNC tube benders can make complex bends to a very high degree of precision that hand formed parts simply can’t match. The machine guarantees consistent bending and precise dimensions.

Co2 Welding

Our Robotic welding infrastructure is capable of welding a high volume of diverse parts and metals with speed, precision and efficiency. Robotic welding automates the welding process to increase accuracy, enhance safety and reduce the time needed to complete each project.

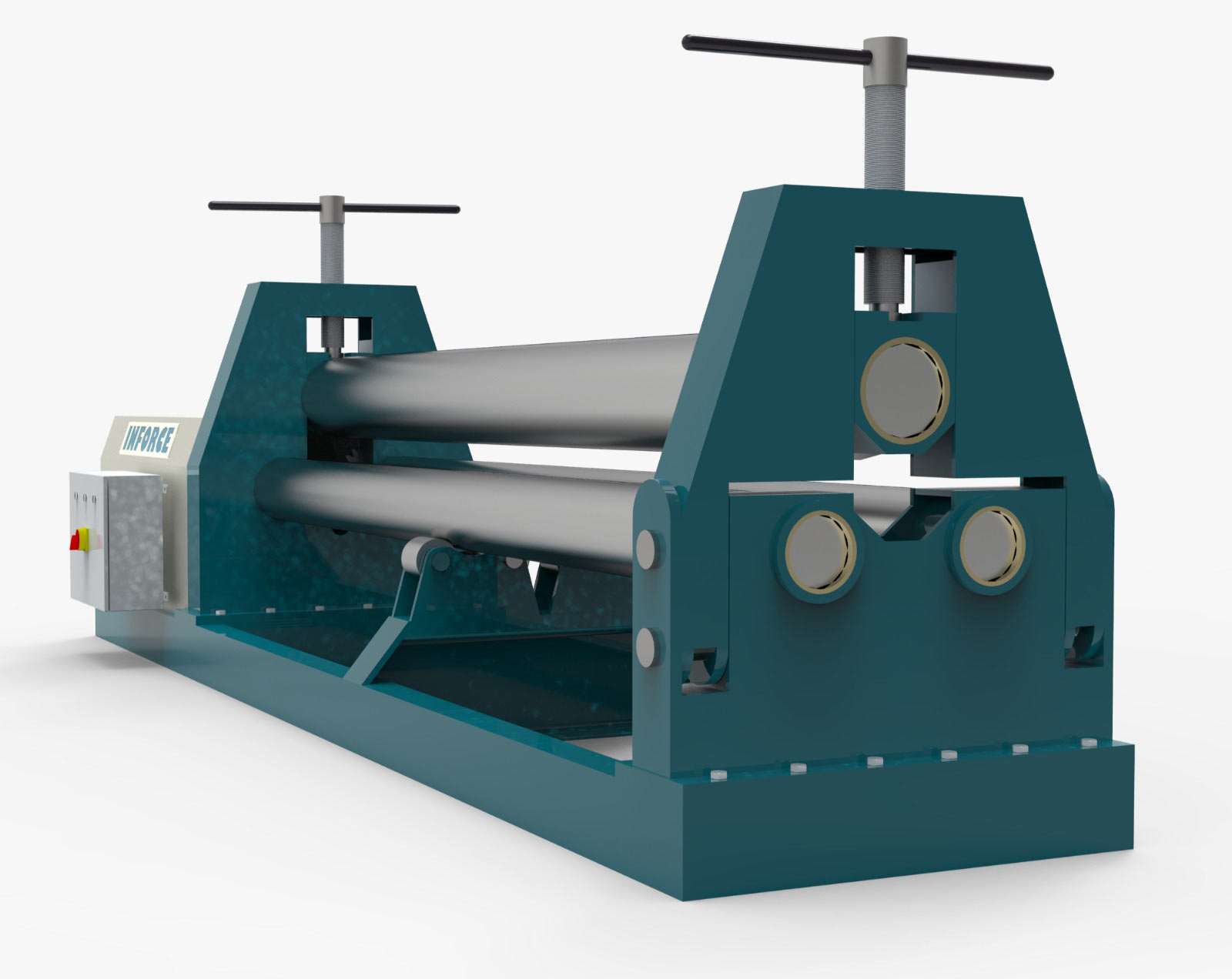

Rolling Machine

A Rolling Machine is an industrial machine used to bend or shape metal sheets, plates, or profiles into cylindrical or curved shapes. It operates by passing the material between rollers that apply pressure to achieve the desired curvature. Rolling machines are widely used in automotive, aerospace, shipbuilding, construction, and metal fabrication industries.

Conventional Machine Setups

A Conventional Machine refers to a manually operated machine tool used for metalworking, woodworking, and other industrial applications. Unlike CNC (Computer Numerical Control) machines, conventional machines require an operator to control cutting, shaping, or forming operations. These machines are widely used in workshops, fabrication units, and small-scale production facilities.